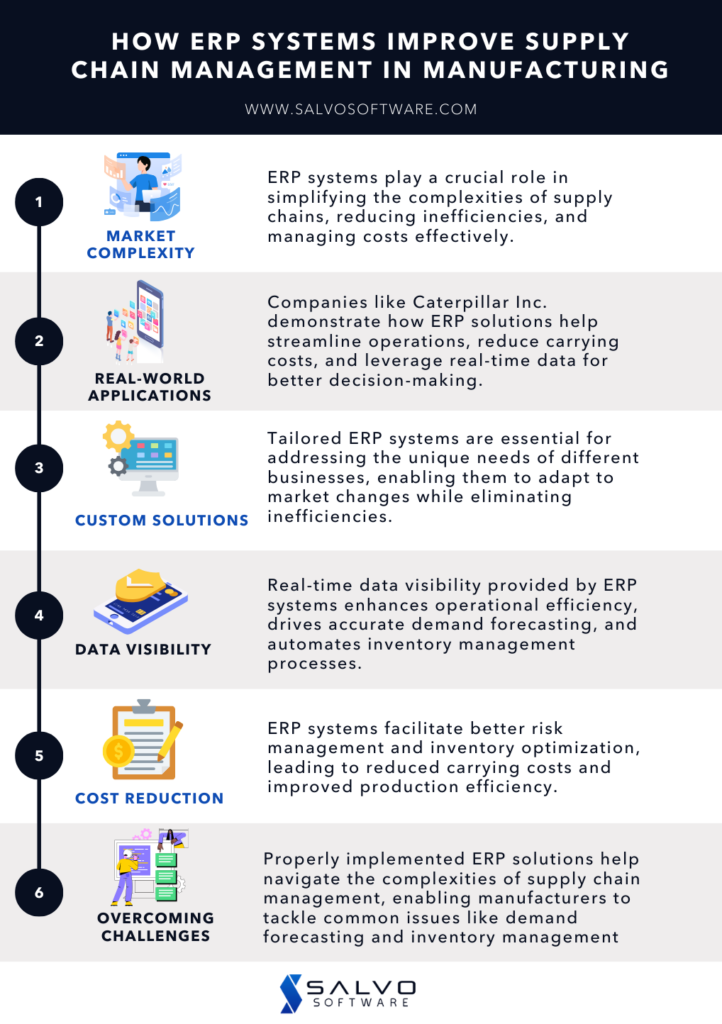

How ERP Systems Improve Supply Chain Management in Manufacturing

Between an ever-changing market and the complexity of supply chains, ERP systems have their work cut out for them. Even a small fluctuation in demand can create opportunity costs.

ERP systems replace complexity with simplicity. When you’ve found the right one, you’ve also found more efficient inventory management, more accurate demand forecasting, and a much smoother procurement process. It’s all about finding the right tool for the job.

ERP Systems in Action

Suppliers, production facilities, distribution centers — supply chain management is a world of complex relationships. It can feel like managing a perpetual crisis.

Companies like Catepillar Inc. know these problems all too well. The sheer size and complexity of their global supply chains are mesmerizing. As the scale of their operation continues to change, growing pains have been a persistent problem.

Caterpillar used an out-of-the-box solution for their ERP system needs. Their results have been solid. Streamlining supply chains reduced carrying costs. The integration of real-time data is almost unavoidably valuable; knowledge is power. So companies like this are prepared when supply chain disruptions appear in the headlines.

But what works best for a billion-dollar multinational isn’t necessarily the best solution for everyone else. Everyone else has their distinct market, their distinct operations, and their own distinct needs.

That’s why our fully custom ERP solutions are adapted to identify, anticipate, and change to match your equally dynamic needs.

FAQ’s

What is an ERP system?

An ERP (Enterprise Resource Planning) system is a tool that integrates all your operations into a single framework, including marketing, sales, HR, and even supply chain management. By combining every bit of your data into one cohesive system, you can enhance data visibility, which opens up a wealth of possibilities for leveraging real-time information, learning with analytics, and automating processes across your business.

But no two operations are identical. An effective ERP system needs to be as adaptable as the business itself when needs are changing. That’s why Salvo aligns your objectives with the technologies most appropriate for the task at hand, eliminating bottlenecks and outdated processes with tailor-made ERP solutions.

How can ERP systems improve supply chain management?

If you’ve ever experienced the impact of delayed information, you already know the importance of real-time data visibility. In supply chain management, the opportunities are endless. Real-time updates on inventory management make it possible to automate reordering at specified thresholds. You can improve demand forecasting with predictive analytics from historical data or market conditions, and burn-away chances for human error.

Having the right tools is crucial, as maximizing the value of ERP systems begins with understanding the distinct requirements of each project. We understand and value unique businesses and create solutions that support your specific processes.

How can ERP systems reduce supply chain costs?

Unoptimized inventory management increases your carrying costs while opening up opportunity costs. Optimizing with ERP systems can make the reordering process efficient and automated. Virtually foolproof.

From cost negotiation to scenario planning, ERP systems enable you to weigh your options, look ahead, and plan for the future. Production efficiency is just the beginning of what ERP systems can do for supply chain management with enormous opportunities to reduce administrative overhead and reduce lead times.

Salvo’s custom ERP systems are built specifically to maximize cost savings in manufacturing logistics; in both development and deployment. Automated inventory tracking, more accurate demand forecasting, streamlined procurement — we identify your unique opportunities to reduce supply chain costs, and then build the solutions best suited to streamline your operations.

What are some common challenges in manufacturing supply chains?

Supply chains can be enormously complicated. From data management to managing transport costs, from keeping pace with globalization to contingency planning… These complexities deal with the unknown, which is perceived risk.

Inventory management issues are endemic to nearly any supply chain. Having too much inventory can crush cash flow. Carrying costs and the risks of obsolescence are at risk of compounding into real losses. Having too little inventory can crush revenue and growth.

Anyone who’s spent time working around a supply chain will understand demand forecasting difficulties are unavoidable. Market conditions are always changing, seasonality causes irregularity.

Natural disasters and the need for supplier collaboration put unexpected bumps in the road. Even the most reliable suppliers can change management, experience disruptions, or otherwise fail to deliver. All the while, as needs continue to change, the procurement process is never bulletproof.

These are problems people have been solving for centuries. But with modern AI systems, it’s possible to create more powerful manufacturing logistics solutions than ever before.

Data can be analyzed in real-time, made actionable, or even power fully automated processes. Our tailored ERP systems deliver the kinds of cost-saving tools that pay for themselves.

How does real-time data visibility benefit supply chain management?

Data can give you insights into trends that you wouldn’t have noticed. It can identify and address risks for disruption as you track inventory, allowing you to respond to changes in supply and demand. You can discover cost reductions through minimizing supply chain disruptions and reducing carrying costs for inventory.

It all starts with the raw, untapped potential of real-time data.

Of course, just because you have the data doesn’t mean you understand it. It doesn’t mean you know how to use it. We specialize in building understandable, actionable ERP systems that are equally insightful and accessible.

Our combination of in-house and nearshore developers provides international expertise solutions scaled to fit your operations and budget perfectly. The results are custom ERP systems provide comprehensive real-time data capabilities that are crafted in your image.

Finding ERP Systems for Supply Chain Management

Looking to find efficiency in ERP systems? Contact us today. We’ll tell you more about how our systems can streamline your operation and what kind of money you’re leaving on the table.

From implementation to live service, we adapt and monitor your tools to ensure they’re always getting sharper.

Whether collaborating with your team or managing your project independently, our dynamic and flexible approach to design has your solutions ready.

The Ultimate Guide to Business Automation: What is It, Why is it Important, How Does it Work?

The Ultimate Guide to Business Automation: What is It, Why is it Important, How Does it Work?  Internet of Things (IoT): A Beginner’s Guide

Internet of Things (IoT): A Beginner’s Guide  ERP Systems: Everything You Need to Know

ERP Systems: Everything You Need to Know  Unlocking Knowledge: Navigating the Future of Education with AI in Learning Applications

Unlocking Knowledge: Navigating the Future of Education with AI in Learning Applications  Crafting Exceptional Experiences: Harnessing Design Thinking for UI/UX Problem Solving

Crafting Exceptional Experiences: Harnessing Design Thinking for UI/UX Problem Solving